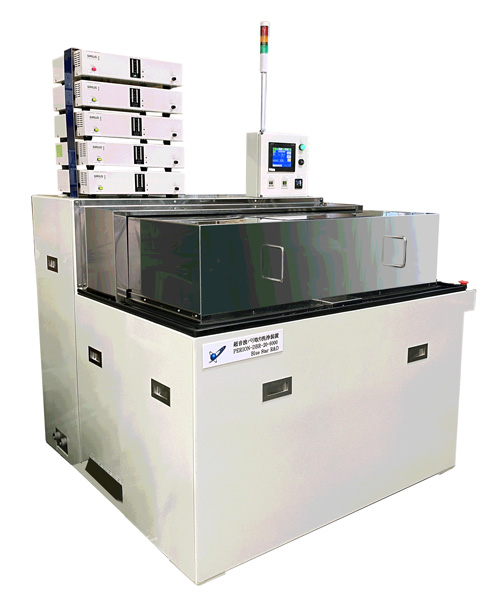

Ultrasonic Barrel Finishing and Cleaning System

PERION-DBR Series(12 models)

Reduce labor costs, stabilize quality, strengthen international competitiveness

A world first! Relief from hard work!

No wastewater treatment required!

Features

This is the world's first ultrasonic barrel finishing system.

No media is used, only liquids, such as water, and strong ultrasonic waves are used for deburring, finishing and cleaning.

Since it does not use media, many ultrasonic barrel operations are light work that can be done by women rather than heavy labor. Wastewater treatment is also not required. Strong ultrasonic cleaning is also performed at the same time, so no post-cleaning is required.

It can be very effective in reducing size and cost of manpower. If you can't believe it, sign up for an experiment.

Target Materials

This is the world's only ultrasonic barrel finishing system that can remove burrs after machining and precision molding of metals, ceramics and their composite materials, as well as wash them at the same time.

We are already active in the fields of watch parts, electric car parts, and various machine element parts (e.g., retainer of a bearing, etc.), and we are proud of our achievements from 1000 to 25000 pieces at a time.

Cleaning Agent

Water, pure water, water-soluble rust inhibitors, hydrocarbon solvents

Model

PERION-□□□-□□-□□□□-□□□-□

□□□indicates DBR, DBUR

□□indicates frequency, 20KHz is 20, 25KHz is 25

□□□□indicates ultrasonic output.

□□□is depth of liquid, which is 75mm, 105mm, 138mm.

□is S for hydrocarbon-based safety increase and internal pressure explosion proof.

Ultrasonic output

2400W

3600W

4800W

Hexagonal rotating cage shape (example)

* Diameter(mm) x Length(mm)

250mm x 300mm

300mm x 400mm

350mm x 500mm

Some models can be used for multiple small baskets at the same time.

Maximum capacity

10kg

15kg

20kg

Ultrasonic generator and transducers

20KHz~280KHz

25KHz~275KHz

For more information, please contact us via email.

Contact Us

中文

中文 Deutsch

Deutsch Español

Español Français

Français English

English bahasa Indonesia

bahasa Indonesia 日本語

日本語 한국어

한국어 Português

Português Türk Dili

Türk Dili Tiếng Việt

Tiếng Việt Русский

Русский